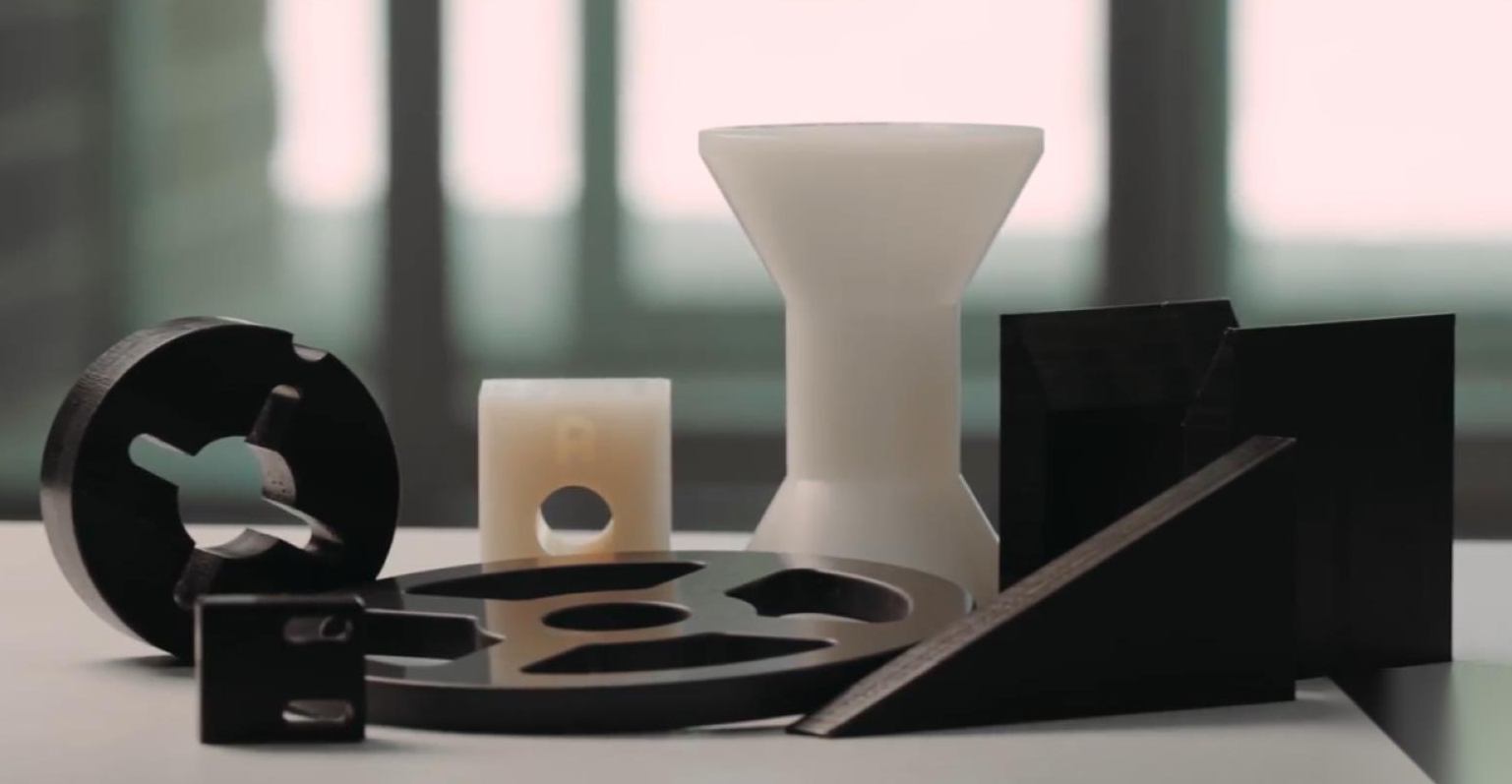

Quality Control

Quality control is important to us here at Plastec Profiles. We invest in our equipment and personnel to ensure that each part that is shipped out the door is made to spec and in tolerance. We can provide fully-detailed inspection and FAI reports. We are capable of handling all levels of PPAP submission requirements as well. Our inspection capabilities greatly exceed our machining tolerances which allows us to consistently measure machined parts.

Inspection Capabilities

- Keyence XM-5000 CMM measuring up to 78.74" × 47.24" × 39.37"

- Keyence IM-8030 IDMS measuring up to 7.87” × 11.81”

- Revopoint Trackit Optical Tracking 3D Scanner ±.005” tolerance

- Complete sets of micrometers, calipers, gauges, and indicators, each traceable and maintained to NIST standards

Plastec Profiles, LLC is an ISO 9001:2015 certified company. We are audited annually by independent consultants to verify that we are following industry standard operating procedures. All of our metrology equipment is calibrated annually as well to maintain consistency and conformity in our manufacturing. Quality control is important to us so that you have peace of mind about the quality of the products you receive!

Ask the Experts

With customized pricing, custom cutting, fast delivery, and free local pick up, we have the solutions you need to stay on schedule! We are constantly expanding our inventory and product lines to meet our customer’s growing needs.

We’re here to help! Whether you have questions, need support, or are interested in our plastic solutions, our team is ready to assist you.

Excellent customer service

Highly skilled, experienced team

Short Lead Times

Extensive Stock

Premium Brands

ISO 9001: 2015 Certified

BBB Accredited

Cart

Cart

Sign In

Sign In