Differences Between Acetal and UHMW

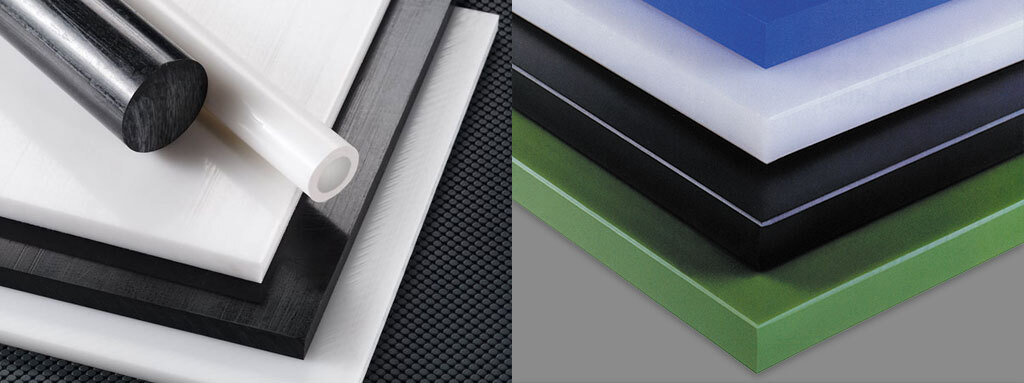

Acetal (polyoxymethylene or POM) is a high strength, low friction engineering plastic that has excellent wear properties in both wet and dry environments. Acetal is chemically resistant to hydrocarbons, solvents, and neutral chemicals. Easy to machine, acetal makes an outstanding choice for applications that require complex, tight tolerances.

UHMW (ultra high molecular weight polyethylene) is an extremely tough plastic with high abrasion and wear resistance. The versatility of polyethylene has made it a popular plastic for countless industrial applications that require durability, low friction, and chemical resistance. Applications include wear strips, chain guides, packaging machinery parts, and marine dock fender pads.

Acetal Material Characteristics |

UHMW Material Characteristics |

|---|---|

| Good chemical resistance Easy to fabricate Good for friction and wear Easy to machine Good for bearings Strong and stiff Good electrical insulation Low moisture absorption |

Good chemical resistance Easy to fabricate Good for friction and wear Easy to machine Good for bearings |

Acetal Applications |

UHMW Applications |

| Bearings and bushings Pump and valve parts Manifolds Gears Jigs and fixtures Food processing and other packaging machinery parts Wear pads Electrical components |

Chute, hopper, and truck bed liners Wear strips and guide rails Star wheels and idler sprockets High-speed conveyors Packaging machinery parts Food processing machinery parts Material handling machinery parts Bumpers, pile guards, and dock fenders |

Acetal Common Brands |

UHMW Common Brands |

| Delrin®, SUSTARIN®, TECAFORM® | Polystone® M, Tivar®, GUR®, LubX® |

Typical Properties of Acetal vs. UHMW

| Property | Units | ASTM Test | Homopolymer Acetal | Copolymer Acetal | UHMW-PE |

|---|---|---|---|---|---|

| Tensile strength | psi | D638 | 10,000 | 9,800 | 3,100 |

| Flexural modulus | psi | D790 | 420,000 | 370,000 | 110,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 1.5 | 1.0 | 18.0* |

| Heat deflection temperature (264 psi) | °F | D648 | 257 | 230 | – |

| Maximum continuous service temperature in air | °F | – | 185 | 195 | 180 |

| Water absorption (immersion 24 hours) | % | D570 | 0.25 | 0.20 | slight |

| Coefficient of linear thermal expansion | in/in/°F ×10⁻⁵ | D696 | 6.8 | 6.1 | 11.1 |

| Coefficient of friction (dynamic) | – | – | 0.20 | 0.21 | 0.10 – 0.20 |

Cart

Cart

Sign In

Sign In