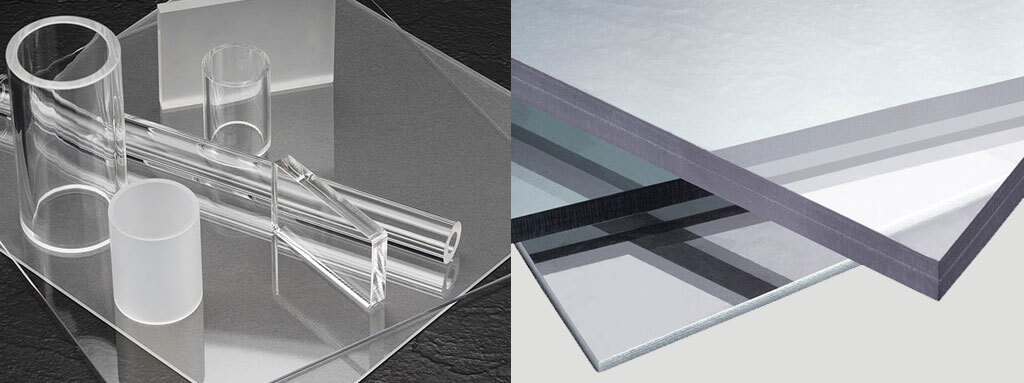

Differences Between Acrylic and Polycarbonate

Acrylic is a transparent plastic material with outstanding strength, stiffness, and optical clarity. Acrylic sheet is easy to fabricate, bonds well with adhesives and solvents, and is easy to thermoform.

It has superior weathering properties compared to many other transparent plastics. Acrylic sheet exhibits glass-like qualities — clarity, brilliance, and transparency — but at half the weight and many times the impact resistance of glass. From durable signs and skylights to eye-catching retail store fixtures, displays, and shelves, acrylic plastics provide outstanding versatility, durability, and aesthetic qualities.

Polycarbonate is a tough, transparent plastic material with outstanding strength, stiffness, and impact resistance. Polycarbonate’s optical clarity makes it ideal for applications such as machine guards, signs, face shields, skylights, POP displays. Polycarbonate is also widely used in architectural glazing for medical facilities, retail and government buildings, and transportation centers at risk from breakage and vandalism.

Acrylic Material Characteristics |

Polycarbonate Material Characteristics |

|---|---|

| Easy to machine Strong and stiff Optically clear Easy to fabricate Easy to thermoform Good dimensional stability Easy to bond Good weathering |

Easy to machine Strong and stiff Good optical clarity (non-machine grade or unfilled) Easy to fabricate Easy to thermoform Good dimensional stability Easy to bond Impact resistant Good electrical insulation |

Acrylic Applications |

Polycarbonate Applications |

| Indoor and outdoor signs POP displays and exhibits Architectural glazing Skylights Transparent manifolds LED-diffusing lighting panels Transportation applications Brochure holders Shelves and retail fixtures |

Indoor and outdoor signs POP displays and graphic holders Architectural glazing Skylights Transparent manifolds Face shields Machine guards Sight glasses Semiconductor machinery components |

Acrylic Common Brands |

Polycarbonate Common Brands |

| OPTIX®, Plexiglas®, ACRYLITE® | TUFFAK®, Sustanat, TECANAT® |

Typical Properties of Acrylic vs. Polycarbonate

| Property | Units | ASTM Test | Acrylic | Polycarbonate |

|---|---|---|---|---|

| Specific gravity (73°F) | – | D792 | 1.19 | 1.20 |

| Tensile strength (73°F) | psi | D638 | 10,000 | 9,500 |

| Tensile modulus of elasticity (73°F) | psi | D638 | 400,000 | 345,000 |

| Tensile elongation (73°F) | % | D638 | 4.5 | 135 |

| Flexural strength (73°F) | psi | D790 | 17,000 | 13,500 |

| Flexural modulus of elasticity (73°F) | psi | D790 | 480,000 | 345,000 |

| Compressive strength 10% deformation (73°F) | psi | D695 | 17,000 | 12,500 |

| Hardness Rockwell M&R, Durometer Shore D (73°F) |

scale as noted | D785, D2240 | M95 | M70, R118, Shore D 80 |

| Izod impact (notched, 73°F) | ft-lbs/in | D256 | 0.4 | 12.0 – 16.0 |

| Coefficient of friction | – | Dynamic | – | – |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 4.0 | 3.8 |

| Heat deflection temperature (66 psi/264 psi) | °F | D648 | – / 195 | 280 / 270 |

| Maximum continuous service temperature in air | °F | – | 160 | 240 |

| Dielectric strength | V/mil | D149 | 430 | 380 |

| Water absorption (immersion 24 hours) | % | D570 | 0.20 | 0.15 |

| Light transmittance (transparency/clarity) | % | D1003 | 92 | 86 |

| Haze (cloudy appearance) | % | D1003 | 2 | <1 |

Cart

Cart

Sign In

Sign In