Differences Between HDPE and LDPE

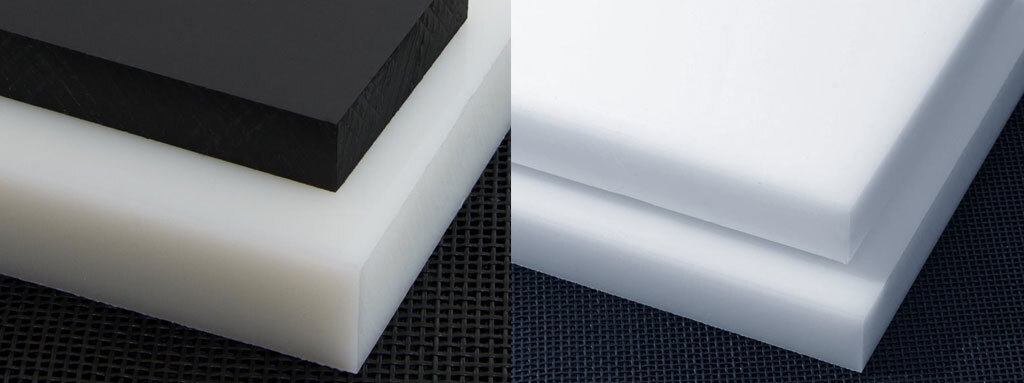

HDPE (high density polyethylene) is a durable, versatile, low-cost, abrasion- and chemical-resistant plastic material . HDPE is easy to fabricate and weld using thermoplastic welding equipment. It is commonly used for fabricated water tanks and chemical tanks.

LDPE (low density polyethylene) is a soft, flexible, lightweight plastic material. It is often used for orthotics and prosthetics. LDPE offers good chemical and impact resistance and is easy to fabricate and thermoform.

HDPE Material Characteristics |

LDPE Material Characteristics |

|---|---|

| Good chemical resistance Easy to weld Low moisture absorption Easy to machine Impact resistant Easy to fabricate |

Good chemical resistance Easy to weld and heat seal Low moisture absorption Soft and pliable |

HDPE Applications |

LDPE Applications |

| Orthotics and prosthetics – AFOs, KAFOs Chemical tanks Cutting boards for food preparation Water pipe flanges (HDPE pipe grade) Outdoor/indoor playground systems Marine construction (pile guards, bumpers) Light-duty tank, chute, and bin linings Outdoor cabinetry and furniture |

Orthotics Prosthetics |

HDPE Common Brands |

LDPE Common Brands |

| Polystone® G, Sanatec®, Orthoform®, Sanalite®, Seaboard®, StarLite®, King StarBoard®, Playboard®, SIMOLIFE, Hitec® | Orthoform®, C-TEK® MODStiff™, Denesetec, TECAFINE® |

Typical Properties of HDPE vs. LDPE

| Property | Units | ASTM Test | HDPE | LDPE |

|---|---|---|---|---|

| Specific gravity (73°F) | – | D792 | 0.96 | 0.92 |

| Tensile strength (73°F) | psi | D638 | 4,000 | 1,400 |

| Tensile elongation (73°F) | % | D638 | 600 | 500 |

| Flexural modulus of elasticity (73°F) | psi | D790 | 200,000 | 30,000 |

| Hardness (Rockwell & Shore D) | scale as noted | D785, D2240 | Shore D 69 | Shore D 55 |

| Izod impact (notched, 73°F) | ft-lbs/in | D256 | – | No break |

| Coefficient of linear thermal expansion | in/in/°F × 10-5 | D696 | 7.0 | – |

| Heat deflection temperature (66 psi) | °F | D648 | 172 | 122 |

| Water absorption (24 hrs immersion) | % | D570 | 0.10 | 0.10 |

Cart

Cart

Sign In

Sign In