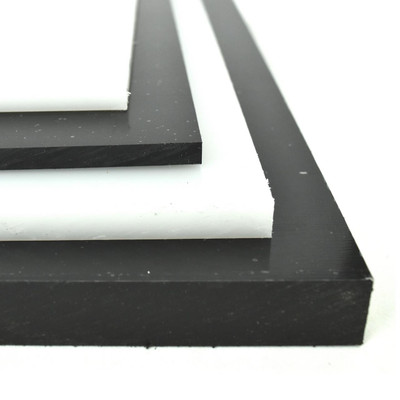

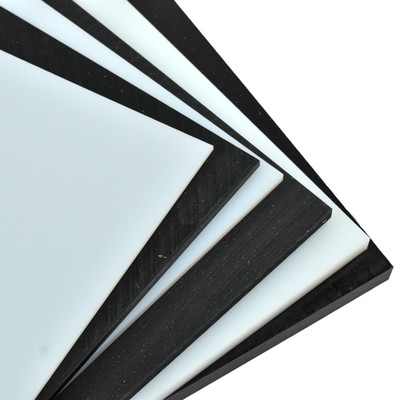

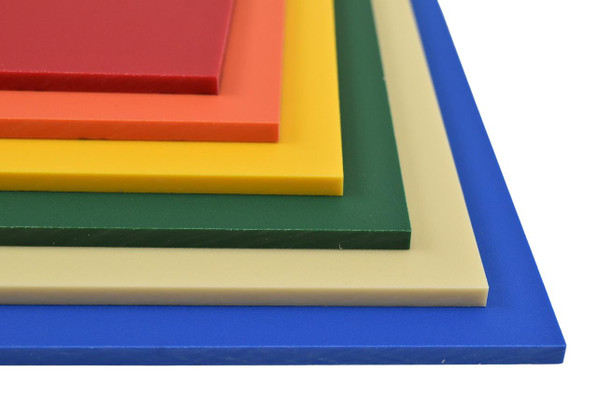

Acetal Copolymer Plastic Sheet Info

Acetal copolymer sheets provide a naturally slippery surface and superior wear resistance. Since they resist expansion from temperature and moisture, they can be machined to close tolerances. Acetal copolymer is good for gears, bearings, bushings and other projects that require precision.

Advantages

- high fatigue and creep resistance

- high toughness, tensile strength and stiffness

- excellent wear properties in both wet and dry environments

- offers potential for reducing part production cost and enables thinner, lighter part design

- low moisture absorption and low friction

- excellent machinability

- good chemical resistance

Applications

- Safety restraint components

- Door system components

- Pump and valve parts

- Food processing and other packaging machinery parts

- Jigs and fixtures

- Gears, wear pads, manifolds

- Bearings and bushings

Cut Tolerance +0" -.25"

| Tensile Strength (psi): | 10,000 |

| Impact Strength (ft-lbs/in): | 1.5 |

| Specific Gravity: | 1.42 |

| Machinability: | 100% |

| Coefficient of Thermal Expansion (in/in/°F x 10-5): | 6.8 |

| Water Absorption (24hr Immersion): | .25 |

| Dielectric Strength (V/mil): | 500 |

| Flexural Modulus of Elasticity (psi): | 420,000 |

| Coefficient of Friction: | .20 |